Japanese Potteries(Explanations to the technical terms of ceramics No.2)

There are various technical words on potteries.

Here are some of those, for which I'd like to give you interpretation one on one.

SUYAKI (Biscuit Firing or Bisque Fired Potteries)

Potteries that are fired in lower temperature and have water absorbency are called SUYAKI, which are usually fired in the range from 700 degrees Celsius to 1,000. Sometimes the word is used for such a way of low-temperature firing.

Many of garden planting pots or so are made of SUYAKI. Probably it's because SUYAKI pots retain water in itself after we give water and prevent inside soil from drying up. Also, in very hot areas, they often use red SUYAKI roofing tiles on roofs. In case of Japan, such is the unique scene in Okinawa located on the subtropical zone, where the tiles of roof retaining plenty rain water in the summer season may cool down room temperature. The water absorbency of SUYAKI is so wisely utilized, isn't it?

By the way, how is it if focusing on the history? Jomon ware came up in 10,000 B.C. was SUYAKI, which was likely used for storing nuts and berries or for cooking. We can imagine that such ware that let air pass through moderately might be suited for storing or cooking. Since those times, for such a long time as 11,000 years, Japanese people have continued pottery production, or kept on making SUYAKI. Unglazed earthenware has been produced not only as household tools but also as burial accessories for mourning. That may be a reason why we kind of feel nostalgia on the faint color and texture of baked clay.

As burial accessories, the Chinese Terracotta Army or Heibayou is well known. Even it's just biscuit-fired, some is pretty heavy as a single body weighs over 100 kg. It might have been hard works even just to move into a kiln. They say that those products had been made with molds, supposed to be divided into several parts like the upper half of the body under the neck and a few separated parts of the lower body. However, from the fact that every body has a different face, there might be craftsmen specialized in making faces. It is also said that approximately 7,000 bodies having each different face could be produced because there actually were respective models. The production of such a big army spent several decades could be described as a group of sculptures superior than the modern art.

500-700 years after that, Haniwa or clay images were made in Japan that were also as burial accessories, but most of them were likely made by Himozukuri (a way piling up strings of clay). It is even natural to consider that molding skills had been already conveyed, however, probably due to the difference of racial characteristics and views of life and death, each respective one of Haniwa has a mood which is rather humorous and relieving people.

HIMOZUKURI (Making it with Strings Made of Clay)

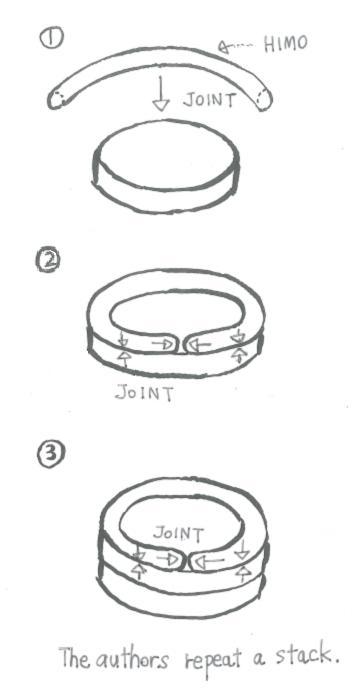

HIMOZUKURI is one of techniques, which had been used since the initial period of potteries, piling up strings made of clay.

It is said that primordial potteries are shaped like both hands ladling water. The shape of a lump of clay hollowed by tapped with an elbow or knee, the shape of that pressed with hands, or the shape of that thrown to the ground; any of them are as big as placeable on hands. A way considered for making potteries bigger than those was the HIMOZUKURI.

Briefly explaining, you prepare some clay as much as you can grip in hand, and go on extending it kneading by palms. So making a few strings that thickness is the same each other, then you just ring-stack one by one and finally smooth the linkage. That's it.

Learning how to make strings, you may be able to make any type of potteries. Only trouble in it is that the works can't be done as quickly as done by a potter's wheel. The work stacking layer by layer is time-consuming, and if you are irritated, it causes differences in level or gaps and then resulted in cracks and tears. If you don't worry about the productivity and make it step by step carefully enough, HIMOZUKURI may be the best technique for you.

TOMBO (It originally means a dragonfly.)

TOMBO is a tool to make diameter and depth of bowls equal, and mainly used for productions with a potter's wheel. It was named TOMBO as its T-shape looked like a dragonfly.

As they need quite many of TOMBO and sizes of bowls vary depending on potters, normally they make it by themselves. For TOMBO to measure diameter, they use a thin strip of bamboo that is cut in an appropriate length. For depth, they cut off a pointed end of bamboo skewer, and then make a hole at the handle part of the skewer and insert a strip of bamboo in it.

Mostly it is made of bamboo probably because of its water resistance and availability, as is often the case that materials for tools are selected by suitability to the tool's nature.